News

UAE DATA CENTER HVAC SYSTEM PLAN

UAE Data Center HVAC System Plan: Integration of Compression Refrigeration and Free Cooling

1.System Principle

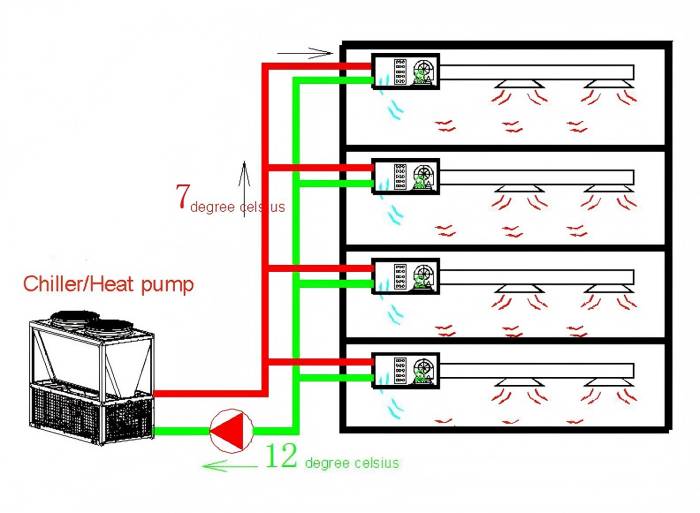

Designed for the UAE’s extreme heat and significant diurnal/seasonal temperature variations, this hybrid system combines an air-cooled screw chiller with a free cooling module, enabling intelligent switching between compression refrigeration and natural cooling modes for maximum energy efficiency.

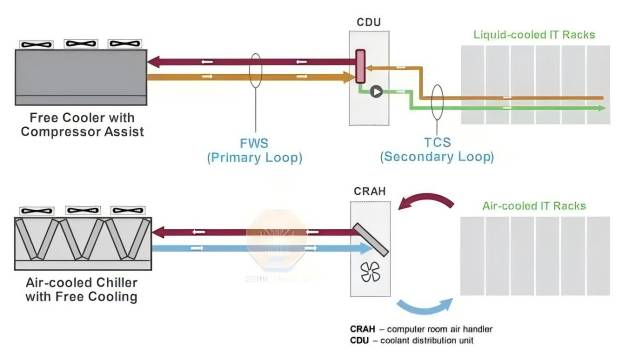

• Compression Refrigeration Mode: Activated when ambient temperatures exceed a set threshold (e.g., >10°C above the plate heat exchanger’s coolant outlet temperature). The screw compressor cools refrigerant, which transfers cold energy to the plate heat exchanger to indirectly cool IT equipment.

• Free Cooling Mode: Triggered when ambient temperatures fall ≤10°C above the plate heat exchanger’s coolant temperature (e.g., at night or in winter). The compressor shuts down, and a free cooling coil uses outdoor air to directly cool the glycol-water solution, releasing heat to the environment with zero compressor energy consumption.

2.Core Components

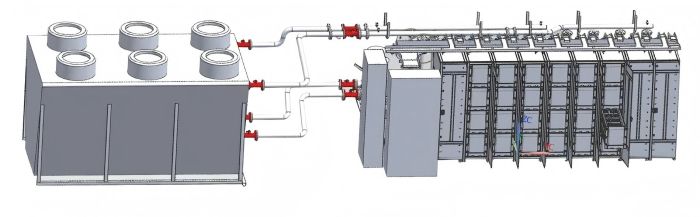

1. Air-Cooled Screw Chiller

◦ High-temperature-resistant screw compressor for extreme UAE climates (>50°C).

◦ Refrigerants: R134a (low-GWP, high-temperature compatible).

2. Isolation Plate Heat Exchanger

◦ Separates the internal glycol-water loop (for IT equipment cooling) from the refrigerant loop to ensure safety and prevent cross-contamination.

◦ Serves as the primary heat transfer hub in compression mode.

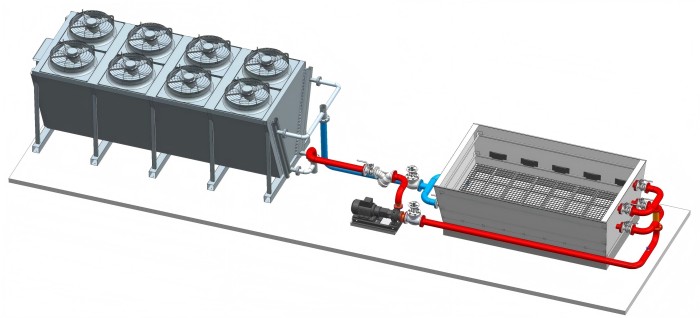

3. Free Cooling Coil (Dry Cooler)

◦ Dedicated loop for glycol-water solution cooling via ambient air.

◦ Equipped with variable-frequency fans to optimize airflow and energy use.

4. Intelligent Control System

◦ Monitors ambient/loop temperatures and load demand for automatic mode switching.

◦ Enables hybrid operation during transitional periods to prevent temperature fluctuations.

1. Operational Modes

|

Mode |

Trigger Condition |

Operation Logic |

|

Compression Cooling |

Ambient temp > PHE coolant temp +10°C |

1. Compressor activates; refrigerant cools glycol via plate heat exchanger. |

|

Free Cooling |

Ambient temp ≤ PHE coolant temp +10°C |

1. Compressor stops; glycol flows to free cooling coil. |

2.Key Advantages

Energy Savings

◦ Free cooling reduces energy use by >70% (compressor off; only pumps/fans operate).

◦ Annual COP improves by 30–40% due to UAE’s frequent nighttime/winter cooling opportunities.

Enhanced Reliability

◦ Reduced compressor runtime minimizes wear; dual-loop design provides redundancy.

Precise Temperature Control

◦ Isolated plate heat exchanger prevents humidity fluctuations, critical for IT equipment.

Sustainability Compliance

◦ Lower carbon footprint aligns with UAE’s 2050 Net Zero Strategy.

3.Applicable Scenarios

• Regions: UAE, Saudi Arabia, and other Middle Eastern areas (300+ high-temperature days/year but winter nights ≤15°C).

• Use Cases: Data centers, telecom base stations, high-density computing facilities requiring year-round cooling.

4.Implementation Guidelines

Climate Adaptation

◦ Free cooling coils require sand/dust protection (e.g., self-cleaning filters).

◦ Glycol solution: 40% concentration (freezing point: -20°C; boiling point: 108°C).

Control Optimization

◦ Add 2°C hysteresis to mode switching to avoid frequent transitions.

◦ Deploy AI algorithms to predict temperature trends and pre-adjust operations.

Cost-Benefit

◦ Initial cost increases 15–20%, but ROI achieved in 2–3 years via energy savings.

5.Advanced Recommendations

• Integrate photovoltaic (PV) systems to further reduce PUE (Power Usage Effectiveness). • Install IoT sensors for remote energy monitoring and predictive maintenance.

This hybrid solution ensures reliable cooling in extreme heat while leveraging natural cooling resources to achieve optimal energy efficiency and operational resilience for UAE data centers

CATEGORIES

LATEST NEWS

CONTACT US

Name: Andy Zhou

Mobile:86 198 0409 1024

Tel:86 198 0409 1024

Whatsapp:8619804091024

Email:sales@datacenterstech.com

Add:Wusi Road NO 4399 Haiwan Town Fengxian,Shanghai,China